Times change, trends change. In the recent past, laminate was the countertop of choice. Over time, that trend gave way to natural stone, like granite, soapstone, or marble. Then quartz came along and became popular. Now, porcelain has entered the countertop market. Not as tile (although that is an option), but as full-size slabs for countertops. The question is: How does porcelain stack up against granite for countertops?

What is Granite?

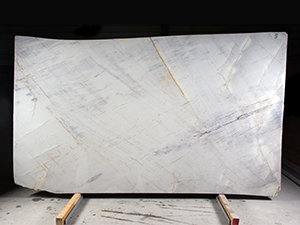

Granite is a 100% natural stone product, created by the ongoing processes of mother nature and the earth. Man finds it and mines it but has nothing to do with its creation.

What is Porcelain?

Porcelain is a man-made product, created by engineers. It contains soft, white clay and various other materials such as feldspar, quartz, ash, sand, and other ingredients. Once mixed, these materials are shaped and then heated to over 2,200 degrees.

Pros and Cons of Granite Countertops:

Pros:

- 100% natural

- Stain resistant – When properly sealed, granite is stain resistant.

- Unique – Not only is each color unique but no two slabs in a color are the same.

- LEED points – Granite can contribute to LEED points in projects.

- Variety – Granite comes in hundreds of assorted colors.

- Readily available – Granite is mined throughout the world.

- Heat resistant – Hot pots and pans can be placed on granite surfaces. (Although trivets are recommended.)

- Repairs – If granite is damaged, it can be normally be repaired by a qualified stone restoration technician.

- Longevity – Granite has been around for thousands of years. It has shown itself to be a stable, beautiful, versatile product we can use for countertops and various other projects.

Cons:

- Seams – Depending on the size of the project there may be visible seams.

- Expense – Granite comes in a wide range of price points, but depending on the look and color you want, it may be costly.

- Damage – Granite is a very durable product but it can be damaged. Chips and cracks can happen if something is dropped on the stone.

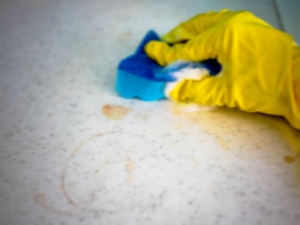

- Maintenance – Granite is not maintenance free. To avoid stains, wipe up spills as soon as possible, and clean with a stone safe cleaner as needed.

- Sealing – Granite sealer is not permanent. Occasionally, resealing your granite may be necessary. This should be done by a qualified stone technician that understands the qualities of your specific granite.

Pros and Cons of Porcelain Countertops:

Pros:

- Heat proof – Porcelain is created with extremely high heat, so the normal heat of hot pots and pans won’t normally harm it.

- Low maintenance – Clean with soap and water. Sealing is not needed.

- UV resistant – Porcelain won’t fade in the sunlight, making it great for outdoor projects.

- Chemical resistant – Acidic foods or harsh chemicals won’t etch, fade, or dull the surface.

Cons:

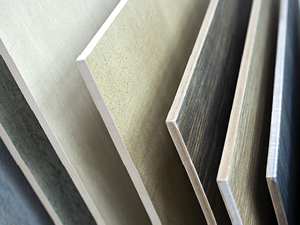

- Edges – Porcelain is a thinner material than granite, so the edge options are limited.

- Variety – Porcelain does offer a variety of colors and patterns but because the countertop aspect of porcelain is still new, it does not have the wide variety of granite.

- Longevity – Porcelain for countertops is relatively new to the market so there are not a lot of statistics or information about the long-term stability of porcelain as a countertop material.

- Expense – While porcelain may not be more expensive than granite, because it is a thinner material, edges may have to be laminated or the countertop may need a backer board, adding to fabrication costs.

- Depth of color – Unless you specifically request through body porcelain (a product where the pattern of the porcelain goes all the way through the slab), you may end up with a color body product. A color body porcelain only has the pattern on top of the slab. It does not go all the way through, so when cut, the edges will not be the same as the top of the slab.

- Cracking – Porcelain, while very durable, can be prone to cracking. Porcelain is a rigid, thinner material making it much more susceptible to cracking during fabrication, installation, and everyday use.

No one product is 100% perfect for every project. It’s best to do the research, and talk to professionals, weigh the pros and cons of each surface and decide which one best suits your needs. Taking these steps will ensure you choose the surface that is best for you.

This article is one of a series of articles written and published on behalf of Surface Care PROS Partners.